Case Study #1

Problem

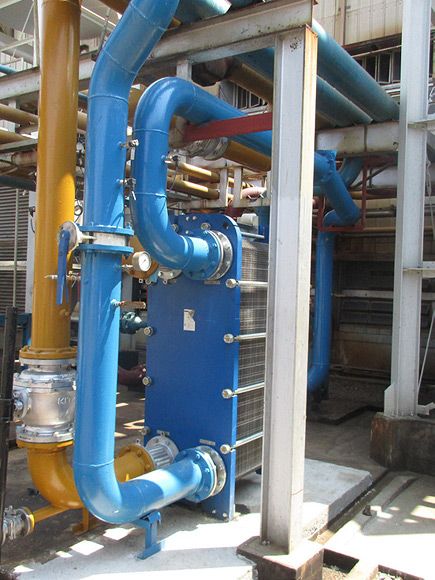

With the existing coolers the luboil temperature could not be kept in the desired range.

Solution

3 sets of much larger coolers. The luboil temperature went down about 10 °C,

and can be maintained well within the recommended limits.

Supplied Parts

• 3 sets of Plate coolers.

• adapter flanges, bolts and gaskets.

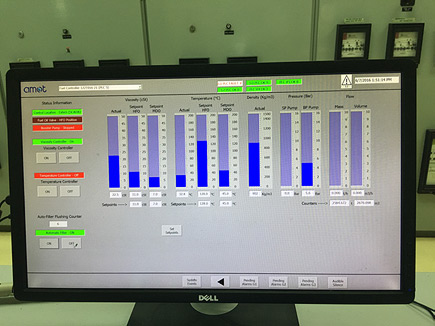

Case Study #2

Problem

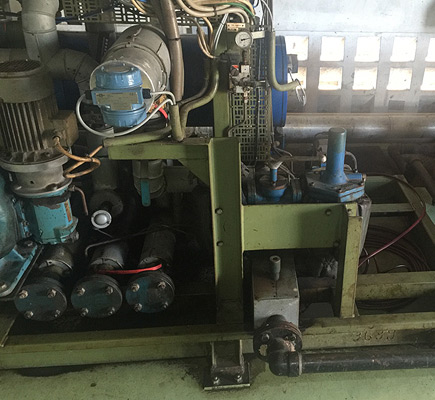

The customer could not use the old automatic backflush filter due to inefficient self cleaning. They were only able to use the manual bypass filter which needed to be cleaned daily.

Solution

• Supply of 2 brand new state of the art automatic backflush filters.

• Due to the bigger sizes the filters were delivered with prefabricated frames and pipes for easy and fast installation.

• The Existing PLC system was upgraded to include the filter control.

• The filter control was also connected to the SCADA system to monitor the performance.

Supplied Parts

• 2 pc filter

• Prefabricated piping and frames

• Electrical material to upgrade the existing cabinets

• New PLC Software

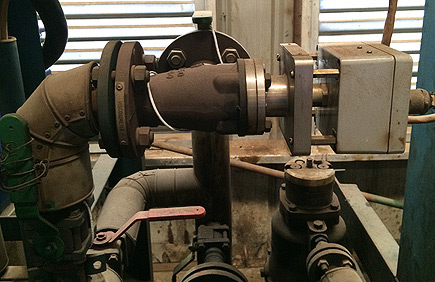

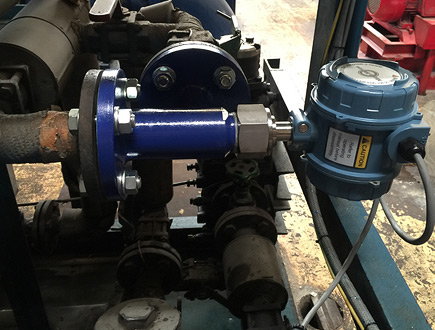

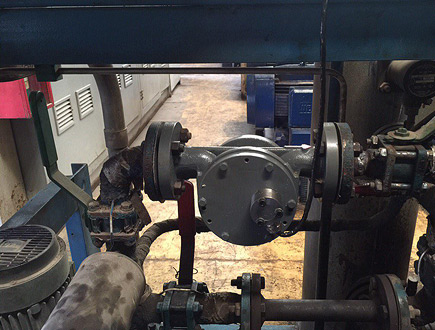

Case Study #3

Problem

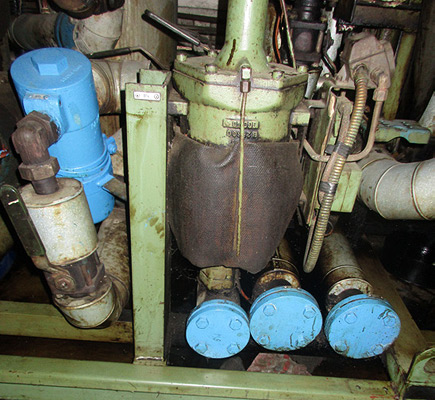

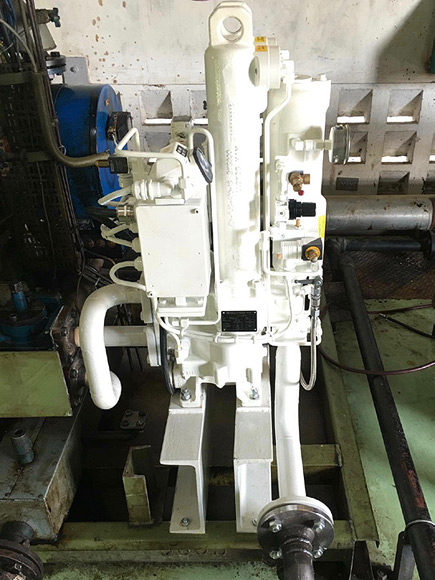

The customer had a defective and obsolete viscosity control system. The original sensors were damaged or the calibration was off. This caused incorrect injection visocity which can lead to expensive engine damages. The flow meter was outdated as well and long overdue for re-calibration.

Solution

• Supply of top of the line viscosity meter with density measurement which will ensure correct signal output of the kinematic viscosity.

• The flow meters where replaced and specially calibrated to have an accuracy of 99.8%.

• The existing controller, control cabinet and all cabling were upgraded.

Supplied Parts

• Viscosity sensor with density measurement

• Flow meter

• Specially designed adapter to install the viscosity sensor without any welding works.

• Control cabinet

• Pressure Sensor

• Cables